Facts About Casters Factory Uncovered

Wiki Article

Examine This Report on Casters Supplier

Table of ContentsA Biased View of Caster ManufacturerGetting My Casters Supplier To WorkCaster Manufacturer for DummiesSome Known Details About Casters Supplier

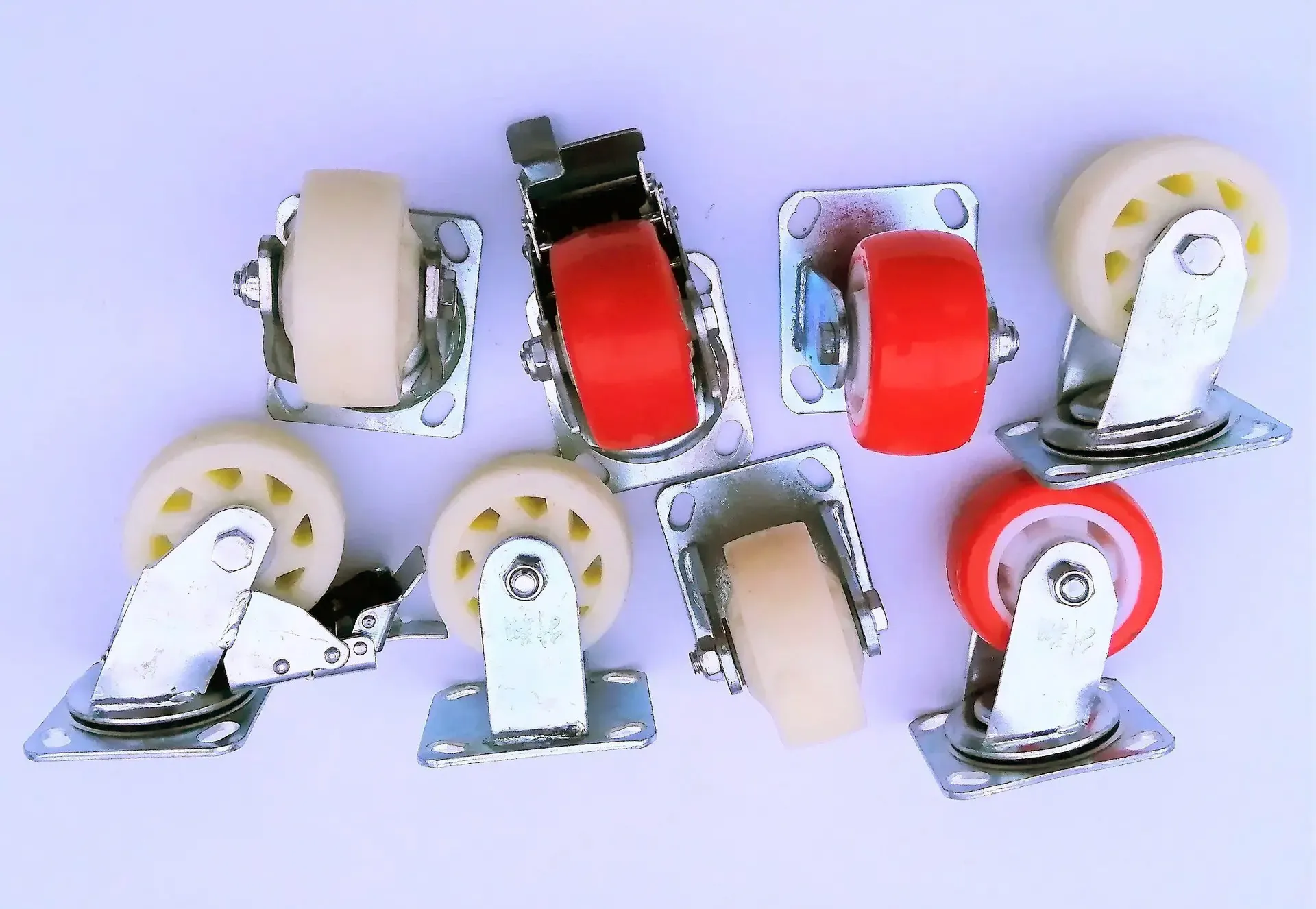

Selection as well as usage of high-quality bit cans is indispensable for the manufacturing of great threads. Leading mills throughout the globe understand odds and ends's precisely why the demand for tailor-maked HDPE is increasing significantly. Provided that the capability guarantee of these cans are originated from its parts, customers are progressively seeking suppliers that use end-to-end bit dealing with solutions.In contrast to what several thought previously, wheels are far more than just wheels. Specialised caster wheels for rotating cans include the place as well as the wheel itself and they make sure smooth bit transportation (as well as top quality stability) in the mill floorings. Casters with various physical requirements (sizes, forms, etc) are available for the various kinds of sliver containers utilized in the rotating procedure.

The casters you choose need to have the built-in ability to fulfill the accurate needs. Some frequently made use of caster wheel materials are: Wheel wheels made with polypropylene are ergonomically created, and also have excellent resistance homes. As a result, they are popularly utilized in position that are subjected to wetness, chemical solvents as well as various other potentially harsh product - caster manufacturer.

Additionally, the material can also operate in rough exterior conditions, as well as is not impacted by solvents either. Casters designed with pliable iron or cast iron boost the loading ability of the item they are fitted with. They are temperature-resistant as well, provide smooth movement, and are not most likely to get broken or damaged often.

Caster China Fundamentals Explained

, like Jumac Cans, typically have both Nylon 6 and polypropylene casters (with zinc-coated bodies) in their profile. Caster wheels are likewise categorized on the basis of their strength rankings, which indicates their load abilities. On this basis, casters can generally be split under three heads: These can normally sustain weights in unwanted of 140 kgs, without any type of substantial flexibility or mechanical troubles - caster wheel manufacturer.

Weights in the range in between 70 kgs and 140 kgs can be mounted on medium-duty casters. Prior to in fact putting on the lots, it is constantly suggested to cross-check the wheel abilities with the maker. As their name suggests, these casters come with the most affordable load-bearing capacity (normally, under 70 kgs).

The wheels can transform on the raceway and also the movement is not restricted to any particular direction. The wheel wheels have actually limited maneuverability, compared to pivot casters. The fixed wheels can only be rolled backward and forward and as such, are not appropriate for sure applications. Considered that the authority when based on high mechanical stress and anxiety commonly creates glitches, the need for 'kingpinless caster wheels' is gradually rising.

An Unbiased View of Casters Supplier

While kingpinless casters are usually more expensive than common swivel casters, their shock-absorption and stress-resistance abilities are dramatically higher. A details kind of caster wheel (that need to be fluff and dust-free) are needed for HDPE rotating canisters.The high shock-absorption capability of pneumatic wheels is obtained from the air filled in them. These wheels are available in both tubeless and also tubed selections.

As a policy of thumb, metal wheels are the hardest of them all adhered to by the plastic casters, as well as ultimately, the rubber casters. The hardness or soft qualities of caster wheels straight affect their movements. Generally, the harder the wheel is, the reduced is their 'rolling resistance'. This, subsequently, makes sure that moving the casters at a consistent rate requires less pressure.

Consequently, softer wheels can function much more 'quietly' than their more challenging caster wheel manufacturer counterparts. The width as well as size of wheel wheels likewise need to be examined particularly when they are being fitted to rotating canisters for smoother sliver handling. Both the 'beginning resistance' and 'rolling resistance' numbers are inversely symmetrical with the wheel size and width.

Getting The Casters Supplier To Work

Due focus needs to be paid to the security aspect. Offered the significance of wheel place on the general performance as well as longevity of the item, a category can be done on its basis too. Stem mount, plate place and also bolt-hole mount (stemless selection) are the usual kinds of installs utilized.Threaded, friction-ring, round, grip-neck, and also square stem types are utilized. Various other ranges, consisting of specialised choices, can additionally be offered. Customers likewise need to inspect the measurements of the wheel stem, or ask the manufacturer concerning the same. Not all caster wheels have similar collections of attributes. There are spring-loaded wheels that are excellent for use in sliver cans.

Casters can also be twin-wheeled in the real estate. Depending on the underlying applications, the wheel setup varies as well (for both swivel casters and also rigid casters).

Report this wiki page